UV offset inks have marked a before-and-after in the evolution of graphic printing. Their ability to cure instantly under ultraviolet light has transformed not only production times but also the quality, durability, and versatility of prints. In an increasingly demanding sector—where speed, sustainability, and regulatory compliance are key—these inks have established themselves as a high-performance solution.

At MA Inks, with over 90 years of experience formulating solutions for the graphic industry, we have integrated UV technology into a wide range of products designed to deliver on-press stability, flawless finishes, and compatibility with the most stringent international standards.

What are UV Offset inks?

UV Offset inks differ from conventional ones by their curing system: they do not evaporate or get absorbed; they polymerize instantly when exposed to ultraviolet light. This process transforms the wet ink into a solid film on the substrate, ensuring clean, precise, and long-lasting results.

Technically, they remain in a liquid state until they receive the exact dose of UV radiation that triggers curing. This photochemical reaction offers clear advantages: it prevents set-off and scuffing, improves register, and allows the printed piece to be handled immediately after it leaves the press.

Moreover, their on-press stability and glossy finish make them ideal for demanding runs, labels, premium packaging, or special publications. Thanks to their high adhesion, they also enable printing on a wide variety of substrates, both absorbent and synthetic or metallized.

Brief history of UV inks

UV inks were born in the 1960s, initially as varnishes designed to protect commercial prints. Their ability to harden quickly upon contact with ultraviolet light made them ideal for improving the durability of printed materials. However, as printing systems advanced and market needs evolved, these formulations developed into full inks, especially in screen and flexographic printing.

In the 1980s and 1990s, offset printing began incorporating UV curing into its processes. This enabled new finishes, faster turnaround, and better resource utilization. Finally, in the 2010s, with the advent of LED lamps and low-energy curing technologies (LE-UV, H-UV), a significant leap was achieved in both energy efficiency and safety. UV inks ceased to be a niche option and became a solution increasingly adopted by conventional graphic printing.

Today, the focus has shifted toward food safety, sustainability, and regulatory compliance. Modern UV inks not only offer high print quality but are also formulated to comply with strict international regulations such as REACH, EuPIA, and the Swiss Ordinance. This makes them a key tool for printers working in regulated sectors such as food, cosmetics, or pharmaceuticals.

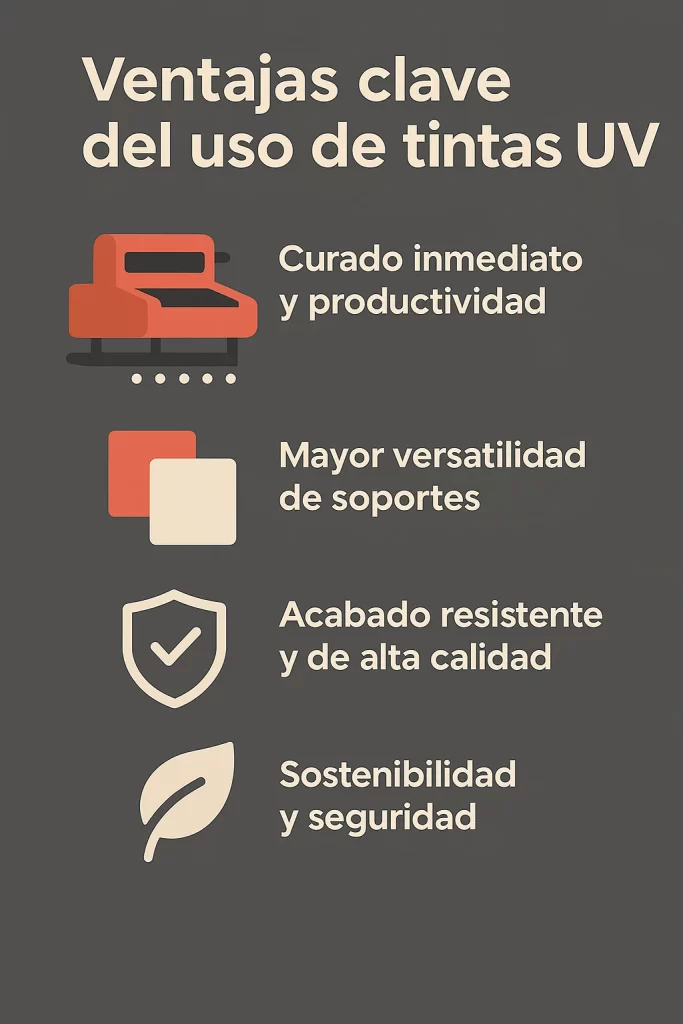

Key advantages of using UV inks

Instant curing and productivity

One of the greatest strengths of the UV system is its instant curing capability. This immediate drying eliminates waiting times and enables uninterrupted production, thereby reducing operating costs and improving the overall efficiency of the print shop. Prints are ready to be handled or move to subsequent processes as soon as they come off the press.

Greater substrate versatility

Thanks to their specialized formulation, UV inks adhere perfectly to both absorbent and non-absorbent substrates. This opens the door to applications on a wide variety of materials: synthetic papers, metallized films, PVC, PET, pretreated plastics, and more. This versatility allows printers to explore new markets without changing technology.

Durable, high-quality finish

Beyond speed, these inks deliver superior visual results. The glossy, clean, well-defined finish, combined with strong resistance to abrasion, moisture, light, and chemicals, ensures far greater durability than conventional inks.

Sustainability and safety

Using UV inks involves lower emissions of volatile organic compounds (VOCs), contributing to safer and more sustainable work environments. In addition, since less energy is required for drying—especially with LED lamps—they help reduce the production’s carbon footprint.

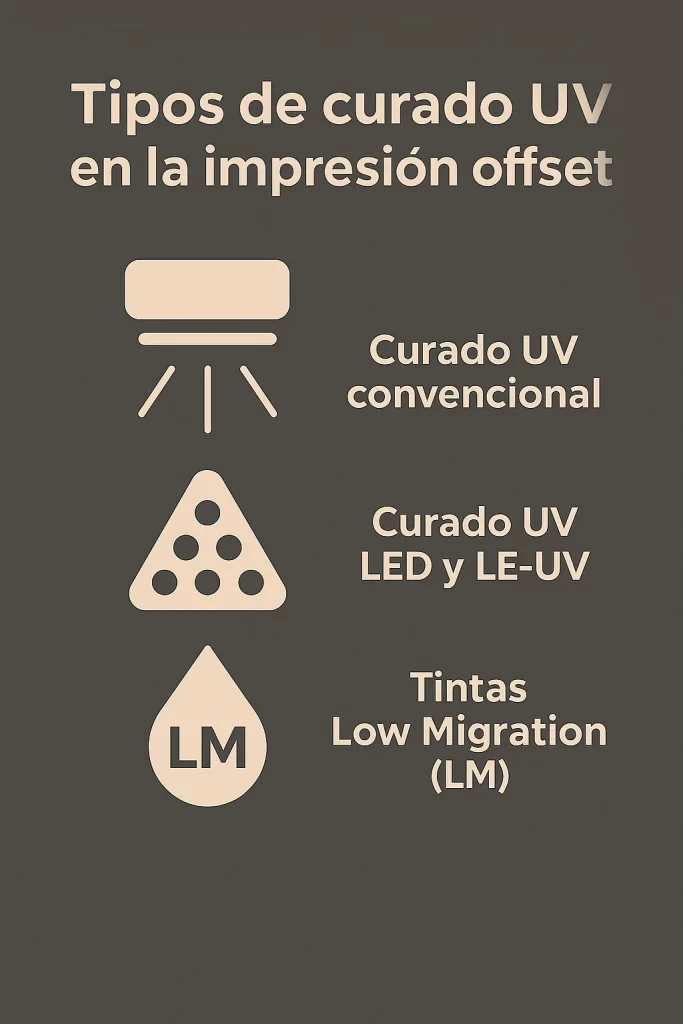

Types of UV curing in offset printing

UV curing can be approached through different technological pathways, each with specific advantages depending on the ink type, substrate, or end application. Below are the three main systems currently used in offset printing.

Conventional UV curing

This is the pioneering system in ultraviolet curing. It uses high-intensity mercury lamps to polymerize inks at high speed. This type of curing is ideal for high-volume production and adapts well to a wide variety of substrates and formulations. However, it consumes more energy and requires proper ventilation systems to manage the ozone generated. It remains a very robust option, especially in environments where a solid infrastructure already exists.

UV LED and LE-UV curing

These more recent technologies have truly revolutionized process efficiency. LED lamps, as they do not generate excessive heat, allow printing on sensitive materials and significantly reduce energy consumption. They also have a longer service life and require no warm-up, speeding up press start-up. LE-UV (Low Energy) and H-UV systems also operate at reduced energy levels but use lamps other than LEDs. Taken together, these solutions offer sustainability, speed, and savings.

Low Migration UV (LM) inks

When the application calls for food safety or indirect contact with sensitive products, UV LM inks are essential. They are formulated to minimize the migration of components through the substrate, complying with regulations such as the Swiss Ordinance or ISO 2846-1. They contain no photoinitiators like ITX or benzophenone and are perfect for printing food, pharmaceutical, or cosmetic packaging. MA Inks offers a specialized range of UV LM inks that combines safety, performance, and visual quality.

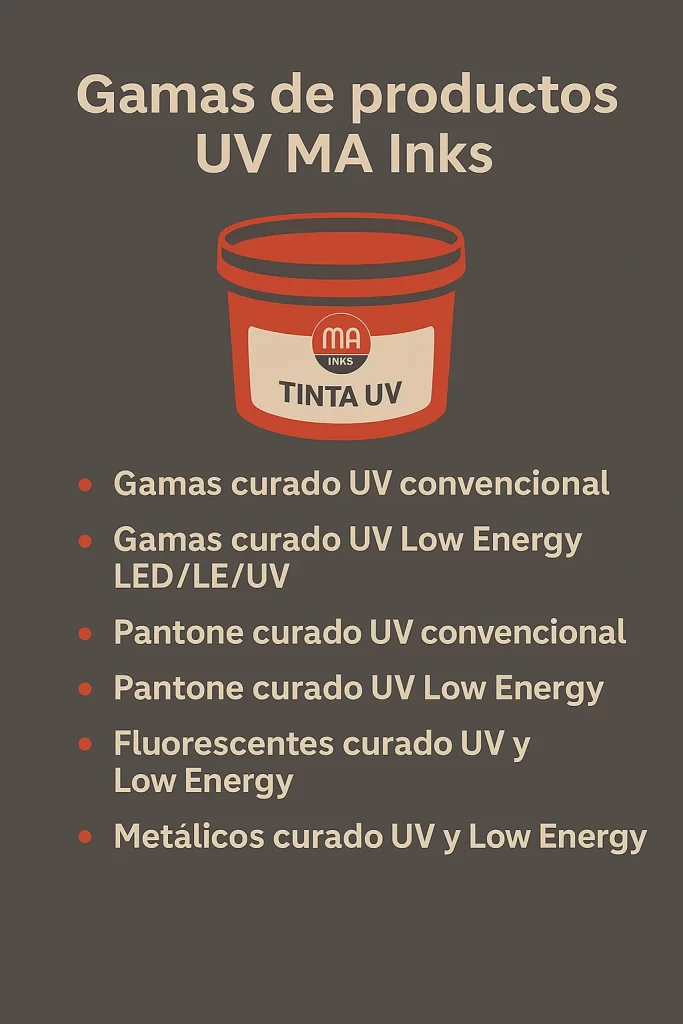

MA Inks UV product ranges

MA Inks’ commitment to quality and innovation takes shape in a comprehensive technical catalog tailored to the demands of the modern printer. The variety of UV inks developed addresses the industry’s specific needs: from high-speed runs on paper and board to printing on synthetic substrates or food packaging compliant with the strictest regulations. Each range has been carefully formulated to ensure on-press stability, excellent lithographic performance, and a professional finish that meets the highest market standards.

Conventional UV curing ranges

UV PAPER: Ultraviolet-curing offset ink for printing on paper and board. It delivers exceptional lithographic performance and enables high-speed operation. Laser-resistant after UV curing and reaches optimal rub resistance at 24 hours. Formulated with renewable raw materials. Suitable for coated and uncoated paper and certain flexible substrates. Not suitable for food-packaging printing.

UV PREMIUM SPEED: Conventional UV-curing offset ink with excellent lithographic properties. Designed for high-speed printing on paper, board, and pretreated plastic substrates. Very stable on press, fully resistant to laser printing after proper UV curing, and offers good gloss and high color strength. Formulated with carefully selected raw materials to minimize odor and reduce the risk of skin and eye irritation. Not suitable for food-packaging printing.

UV PACK: Conventional UV-curing offset ink designed for printing on non-absorbent substrates and also suitable for absorbent ones. Offers an excellent water-ink balance, good adhesion, and great flexibility of the printed layer. Laser-resistant after UV curing. Suitable for coated and uncoated paper, corona-treated vinyl, pretreated plastics, and coated metals. Not suitable for food-packaging printing.

UV PACK LM: Low-migration, low-odor ultraviolet-curing offset ink specially formulated for food packaging on non-absorbent substrates and also suitable for absorbent ones. It features an excellent water-ink balance, good adhesion, great flexibility of the printed layer, and full laser resistance after UV curing. Suitable for coated and uncoated paper, corona-treated vinyl, pretreated plastics, coated metals, and IML (In-Mould Label) applications.

UV BOARD LM: Low-migration, low-odor ultraviolet-curing offset ink specially formulated for food packaging on absorbent substrates. It offers an excellent water-ink balance, good adhesion, and great flexibility of the printed layer. Laser-resistant after UV curing. Suitable for coated paper and board.

Low Energy LED LE/UV curing ranges

UV ECO LED: Low Energy UV offset ink for LED/LE-UV systems. Enables fast curing with minimal energy consumption. Offers excellent water-ink balance, high reactivity, high gloss, and vibrant colors. Very stable at high speeds, with minimal dot gain and clean cut. Suitable for corona-treated vinyl, pretreated plastics, and PP films.

UV LED XP: Low-energy LED-curing UV offset ink designed for printing on paper and board in LED/LE-UV/H-UV systems. Delivers stable, high-quality print results. Enables fast curing with minimal energy, good gloss, and high color strength. Suitable for printing in compliance with ISO 12647-2. Also for corona-treated vinyl, pretreated plastic films, and PP films. Not suitable for food-packaging printing.

UV LED LM: Low-migration offset ink developed for printing with LED / HR-UV / LE-UV / H-UV systems. Suitable for food packaging where the product does not come into direct contact with the printed side. Fast curing with minimal LED/UV energy. Good transfer and on-press behavior. Complies with ISO 2846-1 and ISO 12647-2. Suitable for high-gloss paper and board, corona-treated vinyl, pretreated plastics, and PP films (such as IML labels).

Conventional UV-curing Pantone

Pantone UV BOARD & PAPER: Ultraviolet-curing UV offset ink for printing on paper and board. Delivers exceptional lithographic performance and allows high-speed operation. Laser-resistant after UV curing; reaches optimal rub resistance at 24 hours. Suitable for coated and uncoated paper and certain flexible substrates. Formulated with renewable raw materials. Not suitable for food-packaging printing.

Pantone BASIC UV PACK: UV offset ink for Pantone color formulation, characterized by good adhesion and excellent rub resistance on low-absorbency substrates. Formulated with carefully selected raw materials to minimize migration and odor. Free of benzophenone and ITX. Suitable for high-gloss paper and board, hard and soft vinyl, PVC, varnished metals, and pretreated plastic film.

Pantone UV PACK LM: Low-migration, low-odor UV offset ink with excellent anchorage on multiple substrates. Offers good lithographic properties, good gloss, flexibility, post-curing, and lamination compatibility. Formulated without benzophenone or ITX, with raw materials selected to minimize irritation and odor. Optimal rub resistance at 24 hours. Suitable for high-gloss paper and board, hard and soft vinyl, pretreated plastic film, and PP film for IML labels.

Low Energy UV-curing Pantone

Pantone UV PACK H-ECO: Low-energy UV-curing offset ink, compatible with LED/HR/LE-UV/H-UV systems. Formulated with Pantone®-approved pigments to faithfully reproduce guide colors. Delivers stable, high-quality print results, with good gloss and intensity. Suitable for paper, board, corona-treated vinyl, pretreated plastics, and PP films. Complies with ISO 12647-2. Not suitable for food-packaging printing. Designed for sustainable processes.

Pantone UV LED LM: Low-migration, low-odor offset ink with low-energy UV curing, suitable for LED/HR/LE-UV/H-UV systems. Formulated with Pantone®-approved pigments to reproduce guide colors or as spot colors. Provides stable, high-quality print results with good gloss and high intensity. Suitable for paper and board, corona-treated vinyl, pretreated plastics, and PP films. Complies with ISO 12647-2 and is suitable for food-packaging printing.

Fluorescents — UV and Low Energy curing

UV PACK H-ECO FLUORESCENT Pantone®: Low-energy UV-curing fluorescent offset ink, suitable for LED/HR/LE-UV/H-UV systems. Formulated with ultra-fine fluorescent pigments, it offers excellent anchorage on most non-absorbent substrates. Notable for its brightness, clean fluorescent hue, and on-press stability. Suitable for coated and uncoated substrates and pretreated synthetics.

UV OFFSET FLUOSMART Pantone®: Fluorescent UV offset ink formulated with ultra-fine particle pigments. Notable for excellent anchorage on most non-absorbent substrates, delivering a bright, clean fluorescent effect. Good hue cleanliness, gloss, and press stability. Recommended application: UV OFFSET from 1.5 to 3 g/m². Suitable for coated and uncoated substrates and pretreated synthetics.

Metallics — UV and Low Energy curing

UV PACK METALPLUS R: Low-energy-curing metallic UV offset ink, compatible with LED/HR/LE-UV/H-UV systems. Formulated with metallic pigments to deliver a bright, stable metallic effect. Ideal for printing on coated paper, coated board, metallized paper, PVC, PP, PE, and metallized polyester. Also recommended for synthetic substrates with prior testing. Offers good transfer and definition, high gloss, and stability during printing. Not suitable for food-packaging printing.

UV PACK METALPLUS R LOW MIGRATION: Low-migration metallic UV offset ink designed for applications requiring low odor and indirect food contact. Provides intense metallic gloss, good definition, and excellent stability. Suitable for coated paper, coated board, PVC, PP, PE, metallized polyester, and synthetic substrates (prior testing recommended).

UV PACK H-ECO METALPLUS R: Low-energy metallic UV offset ink designed for LED/HR/LE-UV/H-UV systems. Formulated with ultra-fine bronze and aluminum pigments around 3 microns in size, providing exceptional metallic gloss. Delivers stable, high-quality results with good gloss and intensity. Suitable for coated paper, coated board, metallized paper, PVC, PP, PE, metallized polyester, and other synthetic substrates (prior testing recommended). Not suitable for food-packaging printing. Complies with ISO 12647-2.

UV PACK H-ECO METALPLUS R LM: Low-migration, low-odor metallic UV ink designed for offset printing with LED/HR/LE-UV/H-UV curing. Formulated with ultra-fine bronze and aluminum pigments (average size 3 microns) that ensure exceptional metallic gloss. Offers excellent coverage, high definition in fine details, and great stability at high speeds. Suitable for coated paper, coated board, metallized paper, PVC, PP, PE, metallized polyester, and other pretreated synthetic substrates (prior testing recommended).

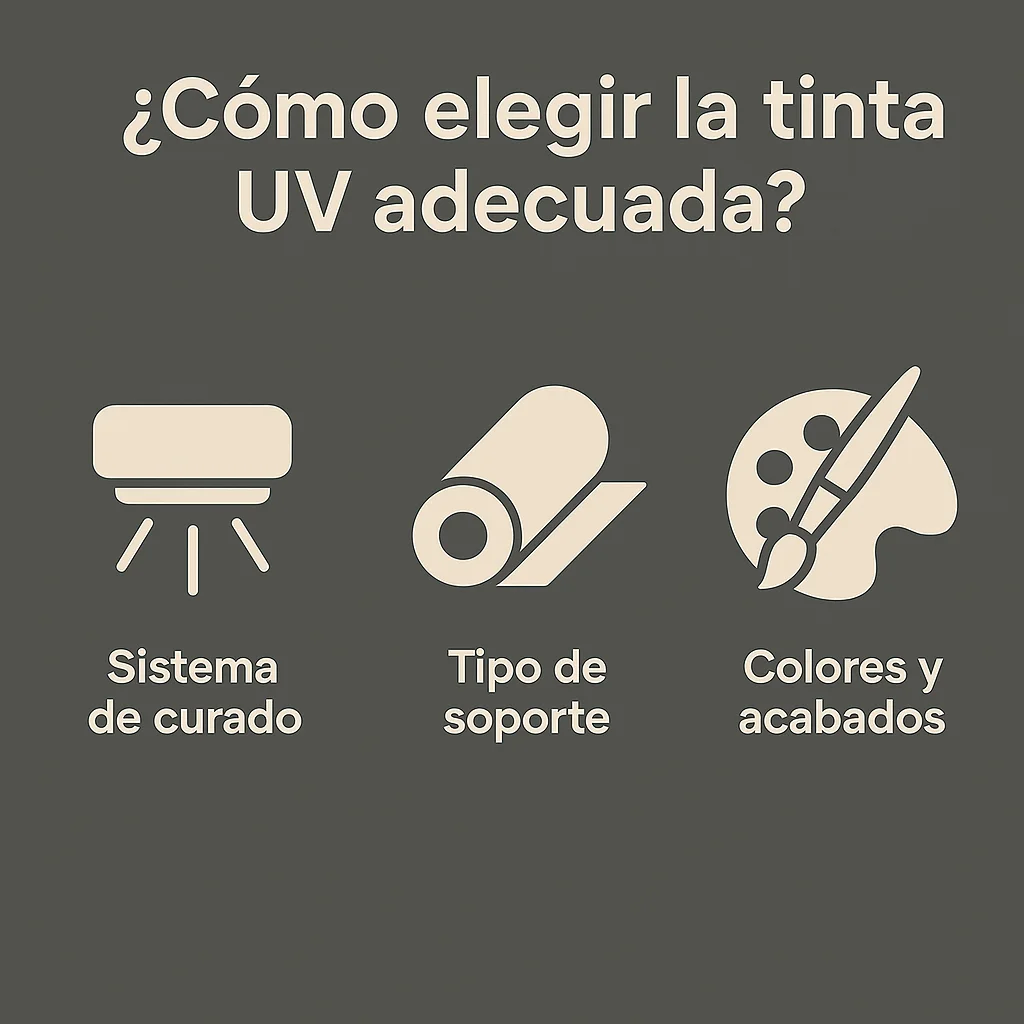

How to choose the right UV ink

Choosing the right ink cannot be left to chance. It is essential to know both the available equipment and the characteristics of the job. A first criterion is the curing type: whether the press works with conventional lamps or LED technology. Each system requires specific formulations to ensure optimal curing and stable on-press behavior.

Another crucial aspect is the substrate type. Printing on coated paper is not the same as on polypropylene, solid board, or metallized materials. The ink must guarantee good adhesion and resistance on that specific substrate. Add to this regulatory requirements, such as the need to use LM inks for food or pharmaceutical packaging.

Finally, factors such as the desired finish, special colors (such as Pantone or metallic and fluorescent effects), and the durability requirements of the print come into play. MA Inks supports this process with personalized technical advice, recommending the most suitable range for each case and ensuring compliance with the main quality standards in offset printing.

MA Inks’ technical and regulatory commitment

MA Inks formulates its UV inks under the highest technical standards. All ranges have been developed without prohibited components such as ITX or benzophenone and comply with international regulations such as REACH, EuPIA, Swiss Ordinance, ISO 2836, and ISO 2846-1. This compliance ensures that their products are safe and suitable for demanding applications.

Beyond formulation quality, the company offers highly specialized technical support. Customers have access to detailed technical data sheets, on-press implementation support, recommendations for downstream processes, and solutions tailored to each production environment.

The company is also certified under ISO 14001, underscoring its environmental commitment. This certification ensures that production processes are carried out under responsible environmental management policies, minimizing waste, energy consumption, and emissions.

Conclusion

UV inks have transformed the way we print, enabling faster, more durable, more sustainable, and more versatile results. MA Inks has embraced this challenge with a comprehensive, technical offering designed to cover every need of the contemporary printer.

At MA Inks, we bring together experience, innovation, and responsibility to offer UV solutions that live up to your projects. If you are looking for quality, regulatory compliance, and true technical support, you are in good hands. Contact our team and discover how we can help you print better, faster, and more safely.