Offset printing vs. digital: choosing between these two technologies is one of the most important decisions in any graphic project. Both offer advantages, but they meet different needs depending on print volume, required quality, delivery urgency, or substrate type. This offset vs. digital comparison examines their differences, applications, efficiency, and sustainability to help you decide which is the best printing option.

What is offset printing?

Offset printing is an indirect system in which the image is transferred from a metal plate to a rubber blanket, and from there to the paper. It uses oil-based inks that repel water, allowing printed and non-printed areas to be separated with great precision.

Advantages of offset printing

- High print quality: great reproduction fidelity, fine detail, and consistent colors.

- Efficiency on long runs: unit cost decreases significantly as volume increases.

- Compatibility with multiple substrates: coated papers, recycled papers, board, synthetic materials.

- Wide range of inks: conventional, UV, vegetable-based, low migration, metallics, Pantones.

- Durability and resistance: ideal for printed products intended for prolonged use.

Limitations of offset printing

- Greater initial setup: requires time to make plates and dial in the press.

- Less cost-effective for short runs.

- Limited personalization: not ideal for variable or personalized printing.

This technology remains one of the most reliable in the graphic world thanks to its precision, versatility, and high quality. According to Smithers’ report The Future of Digital vs Offset Printing to 2029, offset accounted for 37% of global print volume in 2023 and maintains an especially strong market presence, with prospects for sustained growth through 2029.

What is digital printing?

Digital printing is a direct system that transfers the image from the digital file to the paper with no need for plates. It uses technologies such as inkjet or dry toner, which allows great flexibility for short runs and variable data.

Advantages of digital printing

- No prepress costs: prints directly from the file.

- Full personalization: ideal for direct marketing, variable data, and small runs.

- Fast turnaround: an excellent option for on-demand production.

- Less waste on short runs.

Limitations of digital printing

- Higher unit cost on medium or long runs.

- Quality dependent on the device: lower color accuracy in some systems.

- More limited substrates and finishes.

- Less sustainable inks in many cases (toner, cartridges, difficult to recycle).

According to the aforementioned Smithers report, digital printing accounted for approximately 23% of global print volume in 2023, with steady growth in on-demand and personalized applications.

Technical comparison: offset vs. digital

| Feature | Offset Printing | Digital Printing |

| Ideal volume | Medium and high | Low |

| Print quality | Very high and consistent | Good, varies by device |

| Unit cost | Low on long runs | High on long runs |

| Setup time | Requires initial setup | Minimal setup |

| Personalization | Limited | Full |

| Substrate compatibility | Very high | Limited |

| Available inks | Very broad | More restricted |

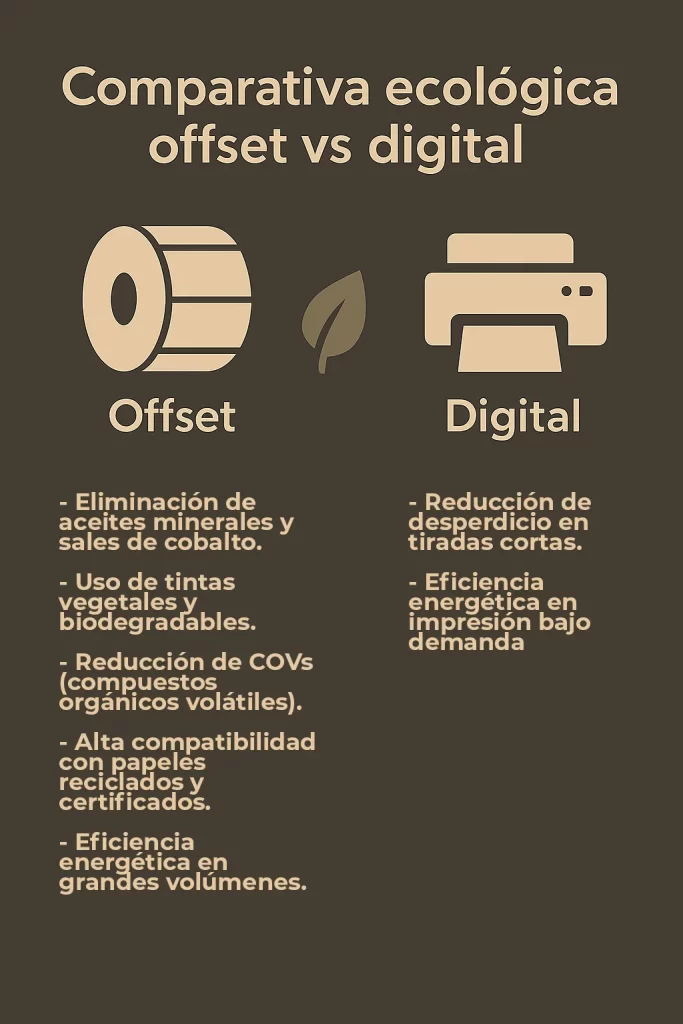

Offset vs. digital: a sustainable view

Offset printing has advanced notably in sustainability, both in the development of new inks and in process optimization and waste reduction. Its compatibility with recycled papers, the use of vegetable-based inks, and energy efficiency on large production volumes make it an increasingly valued option for companies committed to the environment.

Compared with other systems, offset offers clear advantages when factors such as energy consumption per printed unit, recyclability of materials used, and reduction of volatile emissions are rigorously analyzed. These aspects mean that, in many applications, offset stands out not only for its technical quality but also for its environmental profile.

Environmental comparison: offset vs. digital

| Criterion | Offset Printing | Digital Printing |

| Ink use | Vegetable inks without mineral oils, low migration | Synthetic inks and toner, difficult to recycle |

| VOC emissions | Very low with modern inks | Can be high depending on the toner |

| Energy per printed unit | Very efficient on medium and long runs | Higher consumption on continuous runs |

| Waste management | Less waste per unit in optimized processes | Cartridges and components not recyclable |

| Compatibility with eco papers | High: recycled, FSC, PEFC-certified papers | Variable, depends on device and ink |

Sustainable advances in offset

- Vegetable-based inks: formulated without mineral oils, they reduce environmental impact and allow greater recyclability of printed substrates.

- Reduction of volatile organic compounds (VOCs): new generations of offset inks are designed to minimize emissions during printing.

- More efficient curing systems: such as UV-LED curing, which consumes less energy than traditional systems.

- Responsible paper use: being compatible with recycled or certified papers, offset supports sustainable supply chains.

Sustainable advances in digital printing

- Waste reduction: since plates and minimum runs are not required, you can print only what’s needed, reducing paper consumption on very short runs.

- Elimination of chemical processes: by not using traditional prepress processes, developers and solvents are avoided.

- Energy-efficiency initiatives: some manufacturers have optimized the power consumption of their digital equipment.

- First steps toward more sustainable inks: there are developments in cleaner digital inks, although still far from the biodegradability and recyclability of vegetable offset inks.

Environmental impact: offset as a sustainable ally

Thanks to its technological evolution, offset printing not only meets the most demanding technical requirements, but also aligns with today’s environmental standards. In many contexts, it outperforms digital printing in efficiency, waste management, and compatibility with real sustainability policies. It is therefore the preferred option for brands committed to the environment without sacrificing quality.

Conclusion

Offset and digital are not opposing technologies, but different answers to different needs. Digital printing has opened new possibilities in personalization, agility, and on-demand production. It is agile, versatile for short runs, and perfect for variable content. But when we talk about consistent quality, efficiency on large volumes, technical stability, and environmental commitment, offset printing remains the benchmark.

In that analysis, offset printing proves not only to remain relevant, but to be more relevant than ever for graphic-arts professionals seeking a balance between quality, profitability, and sustainability.

Its technological evolution—in materials, inks, energy efficiency, and compatibility with certified substrates—consolidates it as a responsible and strategic option. A mature technology that has not been left behind, but has adapted to today’s context without losing its essence: printing with precision, robustness, and confidence.

MA Inks: excellence in offset ink

MA Inks’ solutions not only guarantee performance and stability, but also address today’s environmental challenges. Our offering of vegetable-based inks, low-migration options, and formulations compatible with low-consumption UV curing strengthens offset printing’s environmental commitment.

At MA Inks we have been over 90 years committed to the evolution of offset ink, developing solutions that combine technical innovation, sustainability, and industrial reliability. Our experience has enabled us to support printers around the world in their processes, adapting to new industry demands without losing sight of what matters most: quality.

Our commitment to agile service, expert advice, and active respect for the environment positions us as a strategic ally for those who choose offset printing as a guarantee of performance.

MA Inks’ offset ink lines

Our range of offset inks is organized into two main lines:

- Conventional Offset Inks: ideal for commercial and packaging printing at high volumes. These inks offer excellent reproduction quality, vivid colors, good rub resistance, and on-press stability. Available in standard and special versions, as well as formulations for metallics and Pantones.

- UV Offset Inks: designed to print on absorbent and non-absorbent substrates, such as metallized papers, plastics, or board. They guarantee intense finishes, high resistance, and instant drying thanks to conventional UV, UV LED, or Low Energy UV curing. Also available in low-migration, metallic, fluorescent, and PANTONE versions.

Want to know which offset ink best suits your process? Contact us and let us help you choose the most efficient, safe, and sustainable solution for your project.